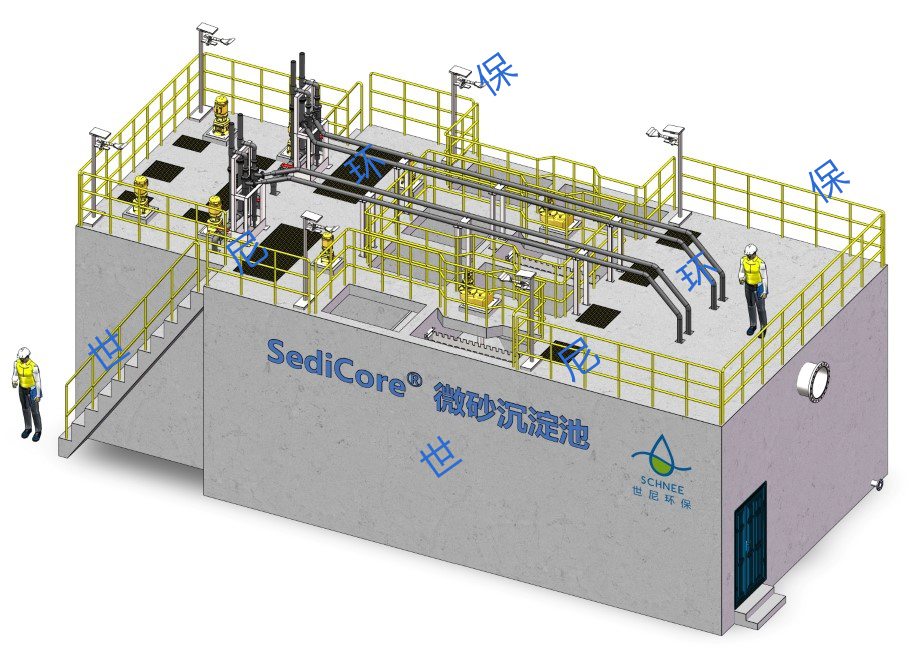

SediCore® Sand Ballasted Floc Clarifier (MBF)

The SediCore® process (MBF Microsand Ballasted Flocculation) is a compact, innovative type clarification system that utilizes microsand as a seed for floc formation. The microsand provides surface area that enhances flocculation and acts as a ballast or weight. The resulting sand ballasted floc dispaly unique settling characteristics, which allow for clarifier designs with high overflow rates and short retention times. These designs result in system footprints that are between 5 and 50 times smaller than conventional clarification systems of similar capacity.

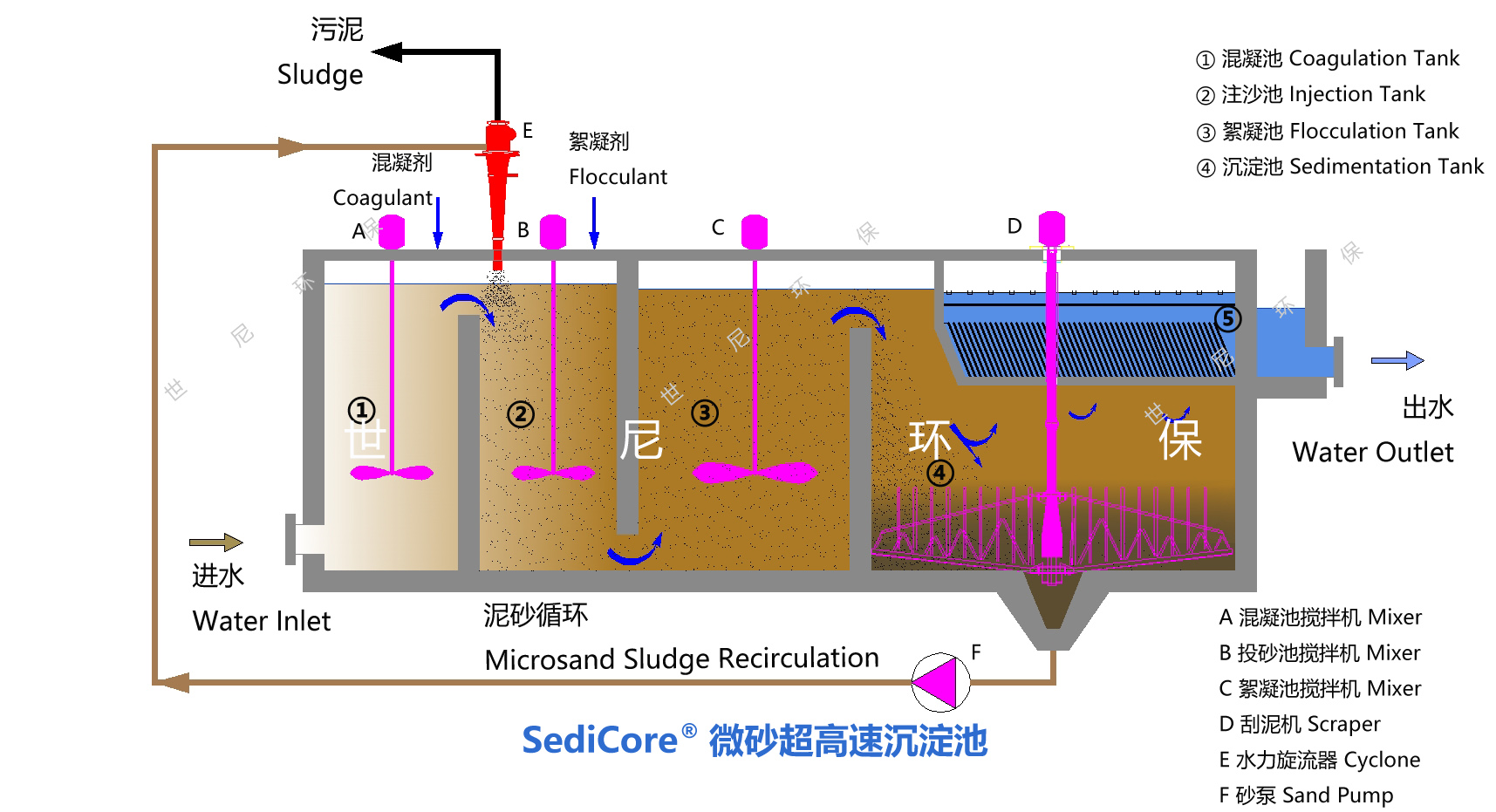

Process Description

Chemical coagulant is added to the raw water to coagulate soluble substances and to destabilize suspended solids and colloidal matter (coagulation) in the influent stream. The coagulated water then passes into an injection chamber, where microsand is added. The floc is fixed to the microsand with the polymer in the maturation chamber, where it acquires weight and volume. Finally, the flocculated water passes through the lamellar clarifier, where the ballasted floc settles and clarified water overflows. Settled sludge, bounded with microsand, is continuously pumped form the bottom of the clarifier and recycled through hydrocyclones, where the microsand is separated from the sludge. The separated sludge is sent to waste and the microsand is recycled back to the process.

Characteristics

● Response time

Inert microsand is always present in the injection and maturation basins and is available to respond immediately once the reactants are added. It is

therefore the ideal system for dealing with storm flows, which by their nature occur very suddently.

● Effluent consistencyIndependent of suspended solids loading, the treated effluent characteristics remain almost constant

● Sludge treatabilityThe good settleability of the sludge allows it to be thickened and dewatered easily.

● Footprint and Capex savingsMicrosand and vigorous mixing considerably reduce flocculation time and consequently the overall footprint of the mixing and flocculation chambers. High up flow velocities (40-120 m/h) produce compact installations and low civil costs, ideal for upgrading existing plants. Efficient use of chemical dosages produces an important reduction in operation costs.

● Stability and flexibilityChanges in raw water charac- teristics (turbidity, color, temperature and total suspended solids (TSS)) do not significantly affect the clarified effluent quality.

The process will accept wide spreads in suspended solids and flow rate (from 0% to 100% in a few minutes) with no effect on effluent quality. The stability of the process simplifies its opera- tion.

● Water of superior qualityThe coagulation/flocculation phase produces a clarified water of superior quality under all raw water conditions.

Products

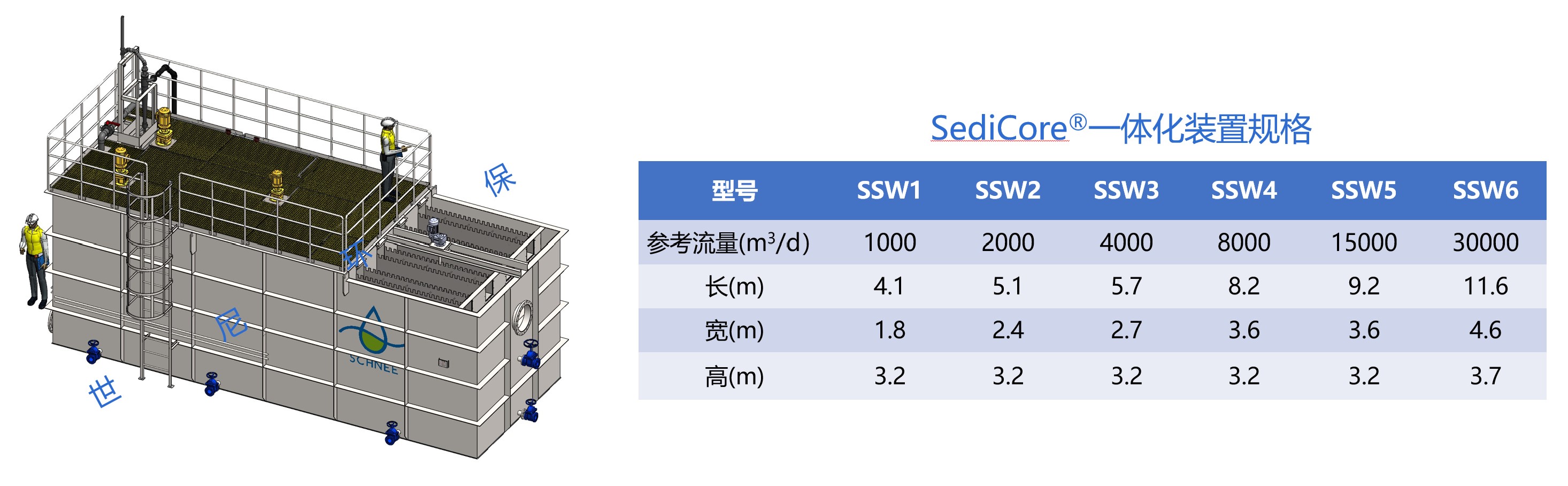

SediCore® Package

SediCore® Civil Engineering